Phone Number

Email Address

Product & Services

Electro Chlorination

On site Electro Chlorination

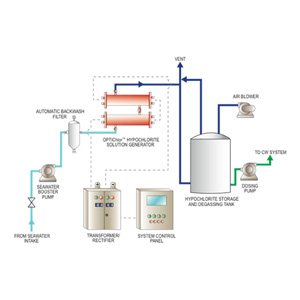

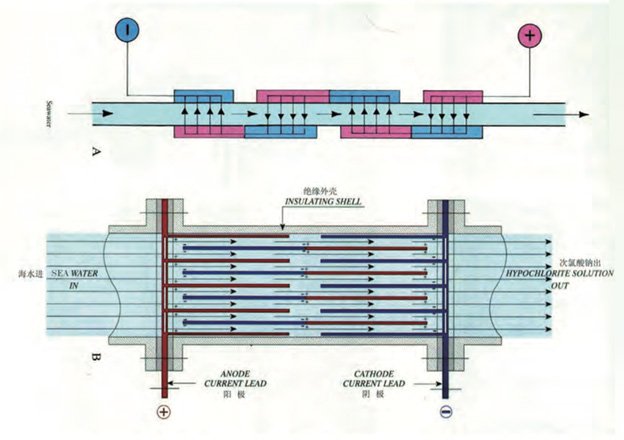

Coastal power plants and facilities require chlorine to control bio- fouling of cooling water circuits and potable water systems. Electro Chlorination (EC) is the safe and efficient on-site production of sodium hypochlorite (chlorine) using salt (from seawater or brine) and electricity. DC current applied to anode/cathode cell pairs in salt solution. Production adjusted to match hypochlorite dosing level required. No storage of elemental chlorine or dangerous chemicals and no dedicated operator required.

Project Success

Clients Reviews

Team Members

Winning Awards

Electro Chlorination Plant

Datong is sole distributor of Wuhan Xingda High Technology Engineering Co., Ltd. (Wuhan Xingda). The company is a high-tech enterprise under AVIC Wuhan Aviation Instrument Co., Ltd. (used name the Aerospace Industry Department Wuhan Instrument Company). It is located at Wuhan East Lake High-Tech Development Zone, nearby the East Lake, is the first researcher and manufacturer of Sodium Hypochlorite Generator in China.

Technology

- More uniform electrode current distribution;

- Smaller ohmic drop between electrolytic cell (as electrode connections are greatly reduced);

- Operating current decrease (operating voltage increases);

- Reducing power consumption, raising current efficiency;

- Structure of electrolytic cell is compact, and the generator space-time production yield was improved.

Anode Coating Technology

According to the seawater feature, DSA (Dimension Stable Anode) anode coating uses the appropriate formula to improve its electric catalytic selectivity, which reduce the chlorine evolution overpotential, increase the oxygen evolution overpotential, to reduce its side effects.

Using modern nanotechnology preparation of nanocrystalline electrode coating (Nanode-2) is multiple oxide nanomaterial preparation of DSA coating. Due to grain refinement (nm), improving the electric catalytic performance of coating and corrosion resistance, it is the most advanced technology of DSA coating currently.

Copyright 2025 - All Rights Reserved By