Phone Number

Email Address

PRODUCT & SERVICES

Biomass Blending Combustion Technology

Co-combustion of biomass and coal for power generation is a comprehensive utilization of traditional and renewable energy, which can not only greatly reduce CO2 emissions, but also has the advantages of economy, high efficiency and environmental protection, and can avoid a series of corrosion and coking problems caused by pure combustion of biomass.

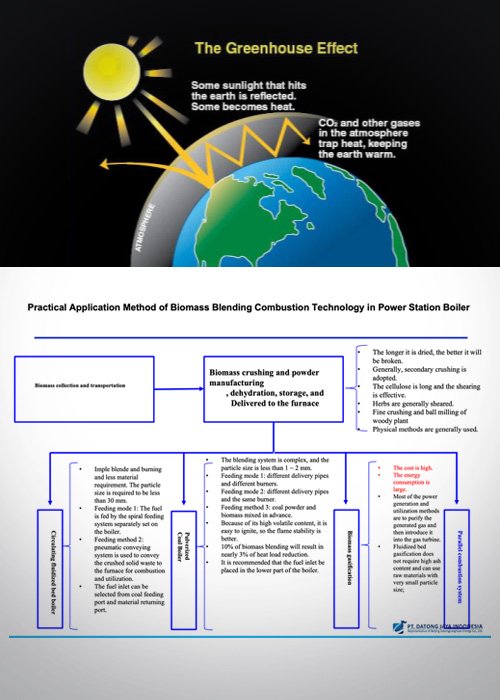

Difficulties of Biomass Application Blending Combustion Technology

- Biomass supply logistics and early feeding scheme:

- The process of biomass transportation mainly includes the transportation of biomass raw materials, the drying of biomass, the cost of making powder suitable for boiler combustion and the transformation of boiler operation.

- The pre-treatment of biomass particles includes heating and drying to increase the calorific value of biomass and converting it into brittle materials that can be ground alone or together with coal.

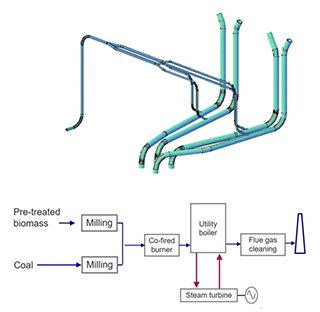

- Effect of Biomass Blending on Overall Combustion and Gasification Performance in Utility Boilers;

- Influence of biomass blending ratio on combustion and gasification characteristics in the furnace.

- Influence of biomass blending position on combustion and gasification characteristics in furnace.

- Effect of Biomass Blending on Heat Exchange Area and Ash Coking Characteristics of Boiler;

- Biomass usually contains a lot of alkali metals, alkaline earth metals and chlorates, and the ash containing these elements usually has a low melting point, so it is easy to cause ash deposition and coking on the heat transfer surface.

- The coal ash in the molten state will become the binder of the newly deposited coal ash and greatly increase the amount of ash deposition.

- Power generation cost and pollutant emission of power plant;

- At the same time, LCOE cost calculation can be used to compare the cost of this technology with other renewable energy generation, and integrate the advantages of biomass blending technology

Copyright 2025 - All Rights Reserved By