Ensuring Reliability for Suralaya’s Mill Upgrade Through FAT and Dome Assessment with Datong’s On-Site Support at the Manufacturer

The Factory Acceptance Test (FAT) is a critical quality assurance milestone in large-scale power plant equipment procurement, ensuring that all systems operate according to contractual specifications before deployment to site. For the Pulverizer Upgrade of Units 5–7 at the Suralaya Sub-Process Plant—formalized under Agreement Letter dated 26 August 2025 — FAT serves as the final verification step carried out directly at the manufacturer’s facility. Through functional tests, component inspections, and performance validation, this process provides essential clarity and confidence for project owners prior to shipment, installation, and commissioning. In parallel, a dome assessment was conducted to review the air-dome application used in China as a coal dome and industrial storage system, offering insights into potential relevance for Suralaya’s operational environment.

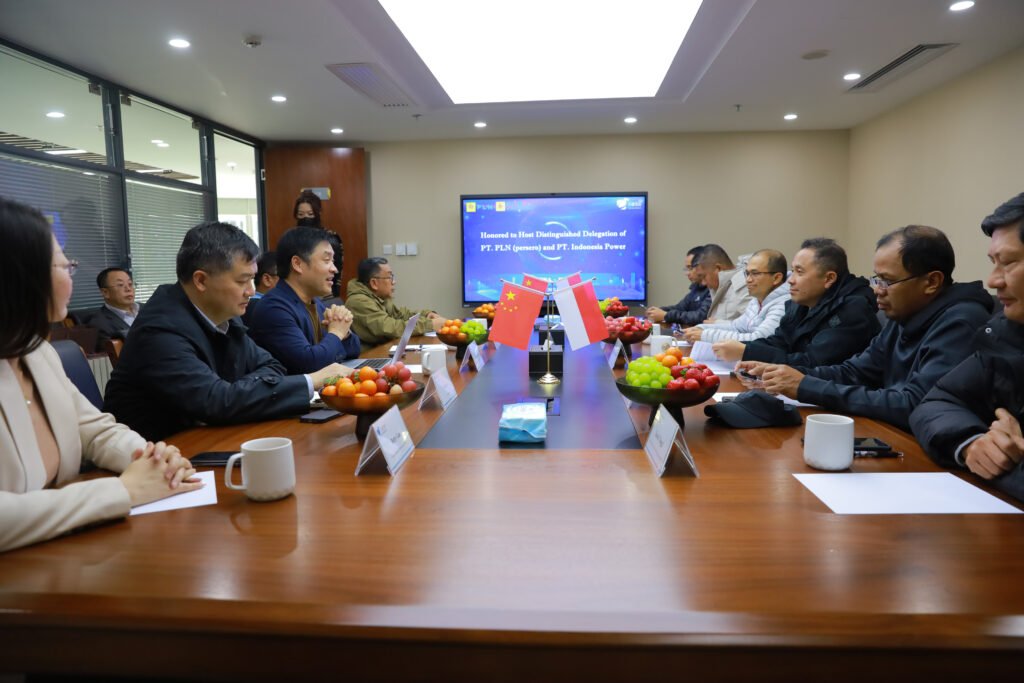

Within the scope of this contract, the FAT visit and dome assessment were among the services arranged for the project stakeholders. Datong Jaya Indonesia—serving as the Indonesian office and the official representative of Beijing DatongLongYuan Co., Ltd.—provided on-site support throughout the activities held from 30 November to 5 December 2025. The schedule included inspections at Beijing Power Equipment Group (BPEG) Manufacture, along with visits to facilities involved in FGD, SCR, and other equipment manufacturing referenced in the FAT invitation letters issued on 5 November 2025. Datong’s presence ensured that test plans, documentation, technical checkpoints, and witness points were properly aligned with the contract, helping PLN (Persero) and PLN Indonesia Power navigate each stage of the manufacturer’s demonstration with structured access to the required data and engineering personnel.

Throughout the program, Datong’s role focused on assisting the PLN delegations in managing the technical processes during their time at the manufacturer’s facility—supporting schedule coordination, guiding the test-witness sequence, facilitating interactions with engineering teams, and ensuring all findings were recorded for downstream execution. This collaboration reflects the operational structure between Datong Jaya Indonesia and Beijing DatongLongYuan Co., Ltd., in which the Indonesian office acts as the local liaison, connecting Indonesia’s project needs with the capabilities and resources of the manufacturer. By providing on-site assistance, Datong helps uphold the clarity of the acceptance process and ensures that all contractual FAT obligations are executed with transparency and technical rigor.

From a technical perspective, the FAT and dome assessment produced insights that are highly relevant for the next steps of the Suralaya pulverizer upgrade. Observations on performance behavior, machining tolerances, and control system responsiveness offer a practical understanding of how the upgraded pulverizer mills will function during operation and maintenance. Meanwhile, the dome assessment provided perspective on structural performance, environmental control, and material integrity, highlighting considerations that would need to be evaluated should similar solutions be applied to Suralaya. These findings contribute to planning for final acceptance documentation, site preparation, equipment interface alignment, and the sequence of shipping, installation, and pre-commissioning activities.

The completion of the manufacturer-level FAT and dome assessment marks a key technical checkpoint for the Pulverizer Mill upgrade of Suralaya Units 5–7. Supported on-site by Datong Jaya Indonesia, the process ensures that each component and subsystem reviewed at the manufacturer is validated against contractual requirements and ready for the next project phase. The documentation gathered through the FAT, along with observations from the dome assessment, now serves as the foundation for preparing shipment, installation, and commissioning activities at the Suralaya site. This structured approach reinforces the importance of comprehensive acceptance testing and cross-border coordination in delivering reliable upgrade work for one of Indonesia’s major coal power assets. Datong remains committed to accompanying PLN and PLN Indonesia Power through each subsequent stage, ensuring that the upgraded pulverizer mills are integrated smoothly and perform as intended in long-term operation.