Phone Number

Email Address

PRODUCT & SERVICES

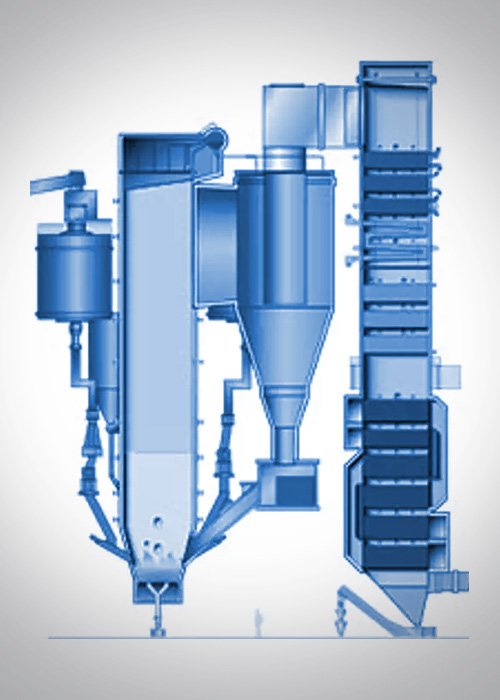

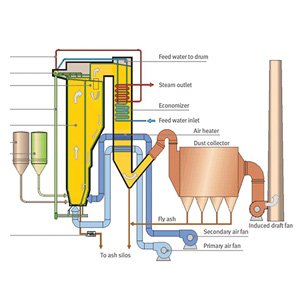

PC and CFB Boiler Optimization and Tunning

The high exhaust gas temperature of coal-fired unit boiler will cause the decrease of boiler efficiency, the decrease of dust remover efficiency and the increase of desulfurization water consumption. After the traditional finned tube low temperature economizer runs for a period of time, the problems of leakage and ash accumulation caused by the wear of the heat exchanger are unavoidable, and the operation economy and safety of the heat recovery equipment are difficult to guarantee.

The temperature of the original flue gas at the inlet of the precipitator in this project is as high as 200 °C, and the content of SO3 in the flue gas is relatively high. After the zero-leakage vacuum heat pipe low-temperature economizer is installed, the specific resistance of the dust is reduced to a certain extent, which can ensure the stable operation of the electrostatic precipitator and meet the requirements of the emission standards. Dust specific resistance is the main factor affecting the electrostatic precipitator charging and dust removal efficiency. The poor operation of the precipitator in most power plants is related to the high specific resistance of coal-fired dust, which easily leads to the secondary voltage of the electrostatic precipitator electric field can not rise, and it is difficult to effectively realize dust charging and dust collection in the electrostatic precipitator. Practice has proved that reducing the flue gas temperature

through the low temperature economizer can reduce the dust specific resistance, effectively improve the secondary voltage of the electric field of the electrostatic precipitator, give full play to the charging and dust collection efficiency of the electrostatic precipitator, thus greatly improving the dust collection efficiency, in addition, SO3 in the flue gas can be effectively collected by the electrostatic precipitator. O as to avoid the problems of downstream equipment corrosion, blue smoke emission from a chimney and the like caused by SO3 escape.

The low temperature and high efficiency coal-fired flue gas treatment system has been widely used in the transformation of ultra-low emission. Regardless of the use of the above In this waste heat utilization mode, the key to the system composition is to arrange a flue gas cooler in front of the electrostatic precipitator. An upgraded heat exchanger (low temperature economizer) based on gravity heat pipe has appeared in the industry, which has been successfully applied in large coal- fired units such as 1000 MW and 660 MW. The biggest feature of this product is that its cooling water (condensate) system is set outside the flue.

Copyright 2025 - All Rights Reserved By